Energy recovery

View the video and our photo gallery..

Sustainable development: our present, your future.

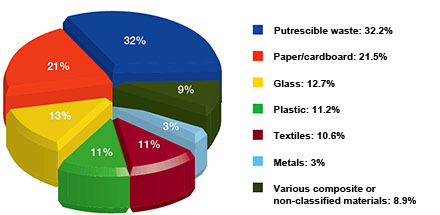

The waste stored in each compartment is probably 80% residual household waste, that is to say household waste separated from recyclable and recoverable packaging waste. In France, this residual household waste comprises on average 30 to 35% putrescible waste and 20 to 25% soiled paper and cardboard. Therefore around 50 to 60% residual household waste is material that can be decomposed (source: ADEME – French Agency for Environment and Energy Management).

Overall composition of household waste – 2007

Overall composition of household waste – 2007

This biodegradable organic matter is therefore compacted as part of the operation of the storage compartment.

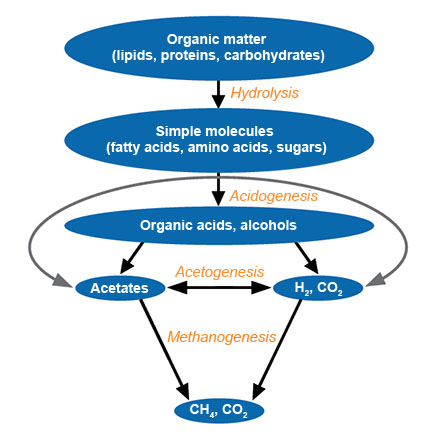

This waste, which is naturally humid, is confined and thus creates anoxic physicochemical conditions (in the absence of oxygen) favourable for developing specific bacteria which decompose the organic matter present in the waste. This decomposition happens in several stages resulting in the formation of methane gas (CH4). This methane along with other decomposition gases like carbon dioxide (CO2) and trace elements formsbiogas.

Biodegradation process of decomposable organic matter

Biodegradation process of decomposable organic matter

As methane is a very significant greenhouse gas (23 times more than CO2) and moreover is very inflammable, many regulatory requirements surround its management. Also, in compliance with current legislation and the latest safety standards, biogas produced on the La Vautubière site was captured, collected and burned off in a customised gas flare. The facilities necessary for collecting biogas in 2006 were as follows:

- regularly spaced shafts and drains in the waste pile ;

- a network of pipes connecting the different shafts and drains ;

- a suction unit sucking, through a network of pipelines, the biogas produced by decomposition ;

- a gas flare with a control command and measuring cabinet.

From the network of shafts and burning that existed in 2006, the flow of biogas collected at the La Vautubière site was in the order of 300 m3/h, with the biogas containing around 25% CH4. Given the development potential of the capture network and new tax provisions encompassing the energy recovery of biogas, with notably the implementation in 2008 of an energy buy-back rate, SMA Environnement became interested in the production potential of the La Vautubière site and its possible upgrading.

In 2009, SMA Environnement launched, with the financial aid of the French Agency for Environment and Energy Management ADEME and the Provence-Alpes-Côte d'Azure Region, a feasibility study for the recovery of biogas by combustion in a motor with an electric generator.

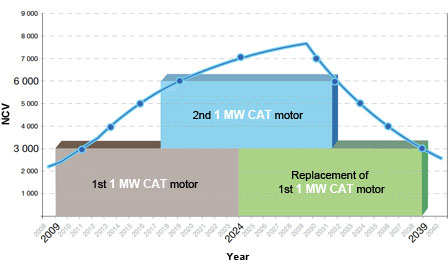

This study enabled the site's biogas potential to be estimated at around 1000 m3/h over the first 7 years and even 1500 m3/h over the following 10 years. After researching the possibility of selling heat cogenerated by the combustion of biogas from the processing of neighbouring industrial facilities' sludge, having an on-site application to process the site's leachates by forced evaporation turned out to be more relevant.

The technical conditions for succeeding in this recovery also depended on the choice of electric generator, the connection distance to the adapted electricity network, the quantity of leachates to be heat treated, and, above all, the installation of drainage features and means for adjusting the biogas collection network, in order to quickly increase from 300 m3/h to around 1000 m3/h minimum and from 25% CH4 to more than 40%. SMA Environnement therefore undertook, with the support of its technical partners (CFERM Engineering, ENERIA and PRODEVAL):

- the creation of a network of around 60 shafts and 5 biogas drains (more than 6 shafts per hectare) ;

- the installation of low-permeability covering layers around the shaft heads, in order to avoid the entry of unwanted outside air containing oxygen unsuitable for the development of methanogenic bacteria ;

- full renovation of the existing network in order to prevent low points creating siphons blocking the suction of the drained biogas ;

- the choice of a CATERPILLAR® biogas motor of 1 MW electrical power and associated equipment (biogas purification silos, air coolers, electric alternator, etc.) ;

- the sizing of a platform able to facilitate the installation, in the short term, of a second 1 MW electrical motor ;

- the sizing of a treatment by forced evaporation NUCLEOS® plant, for around 2400 m3 of leachates produced on the site per year (5–7 m3/day).

Projected curve of biogas production and potential energy production

Projected curve of biogas production and potential energy production

Simultaneously, SMA Environnement took the necessary steps with the electricity network distributor (ERDF – French Electricity Distribution Network) to connect to their network, and drafted a request for an additional prefectural decree to permit installation of the electric recovery unit for biogas produced on the La Vautubière site. The various works were finished at the end of 2009. Additional requirements to the prefectural authorisation, concerning the operation of the biogas recovery unit, were stipulated in June 2009 and official connection to the electricity network took place in January 2010.

For this purpose, SMA Énergie, a subsidiary of SMA Environnement was established.The operation of the current plant is described in the diagram below and the photos illustrate the different facilities put in place.

At the present time, the production of biogas has reached 800 m3/h with an average methane concentration of 39%. The electricity production conforms to predictions with a 1 MW electrical motor. The installation of the second 1 MW electrical biogas motor is planned for a year's time. Please note that the regulation and monitoring of the plant is carried out with daily visits to the site and at a distance by phone. The various maintenance operations correspond :

- to the cleaning of evaporation units,

- to the control and replacement of active carbon used for purifying the biogas,

- to the regular flushing of the motor,

- to the regular adjustment of the collection network,

- to the environmental monitoring of the plant with quality control of combustion fumes,

- to quality control of leachate vapour emissions with monitoring of Legionnaire's disease,

- ...

PTo build this recovery unit, SMA ENERGIE joined forces with its partners :

Download the biogas energy recovery leaflet